No matter the quality of your forklift truck, after a few years of service in a busy and fast-moving warehouse, it’s not going to have quite the same performance as it did when it was brand new.

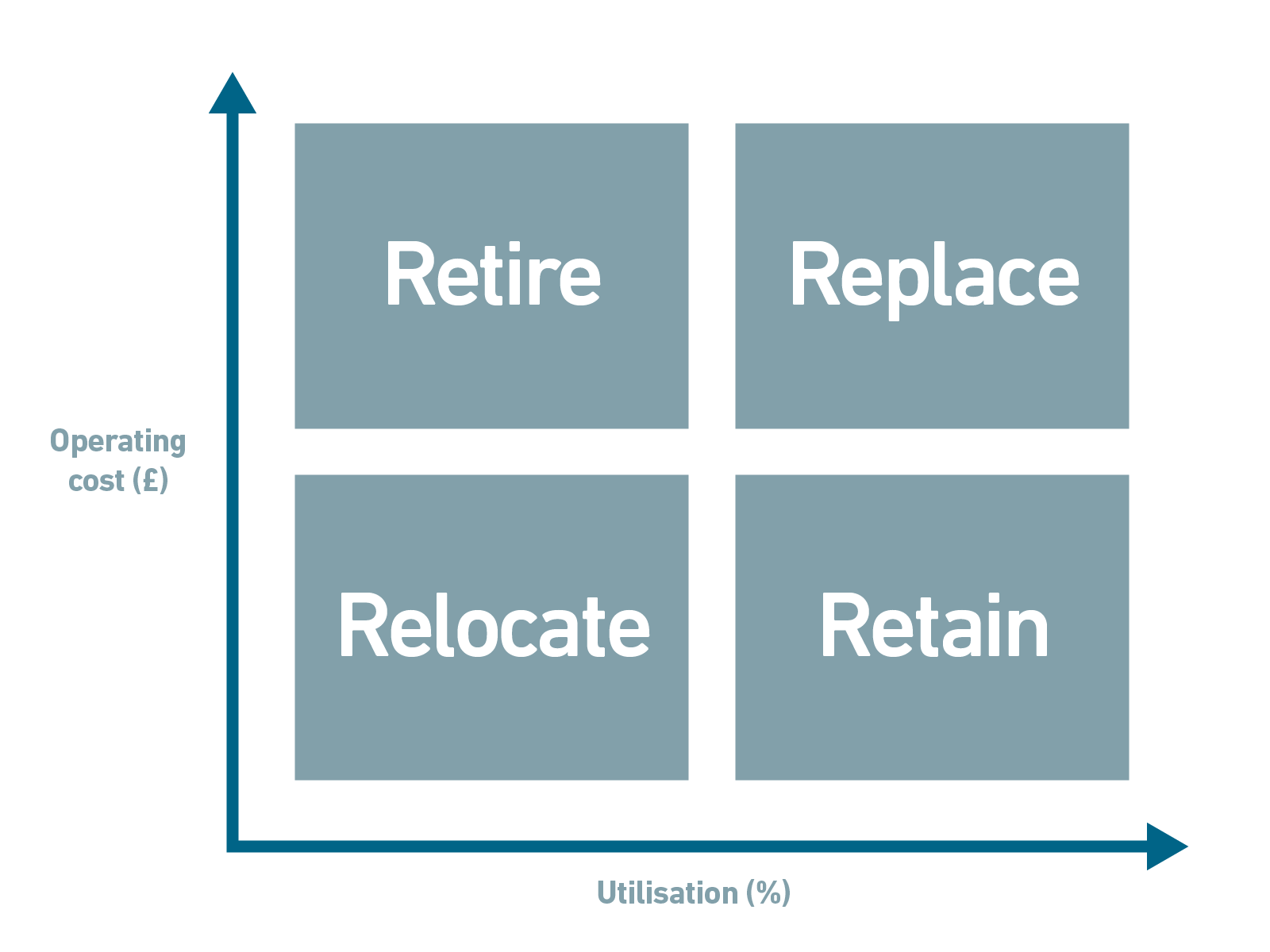

Productivity and efficiency in the warehouse can really suffer once a forklift becomes too unreliable, and the time will always come when you need to replace it. But how do you know how long a forklift should last? And are there any alternatives to replacement? The diagram below should give a clear idea of what your options are, and when you should consider them.

Starting from the top-left:

If utilisation is low, and operating costs are high: retire

If the long-term costs of maintenance begin to overtake the cost of new equipment, it’s time to get rid of your truck. You can feel confident that retiring the truck to bring down costs is the best move. By examining your operation, you can probably find a better way to use resources than keeping a truck a truck in this condition.

If utilisation is high, and operating costs are also high: replace

If you're not sure how long a forklift should last, this is the ratio you should be looking at. A truck like this may have reached the end of its economic life. This could be due to reliability issues, as that can mean frequent maintenance — a common problem with trucks which see a lot of use.

However, a truck with high utilisation is clearly needed in the warehouse. For this reason, replacing the forklift would probably be your best option, especially if the cost of the replacement is less than the cost of maintenance on your current truck. The improved ergonomics, better safety features and high efficiency of modern equipment could also help you save even more money.

If utilisation is low, and operating costs are also low: relocate

If it’s not costing you much money and isn’t being used heavily, you don’t have much reason to retire or replace this truck. However, if you look at your operation, this truck could potentially be better used in a less busy area of your facility. A typical relocation would be moving a truck like this from a factory’s distribution area over to production, where it may not be in constant use and where it’s not as critical. This option may be good for older trucks which are being replaced by newer equipment. They should be able to handle these less-intensive tasks in their old age.

If utilisation is high, and operating costs are low: retain

You’re in a good position! It looks like this truck is aiding your work in the warehouse in a cost-effective way. For many warehouse managers, there would be few reasons to consider retiring or replacing a truck which fits this description.

Figuring out which of these situations you’re in requires regular fleet review sessions with your supplier. After looking at things like maintenance costs and downtime, they’ll be able to advise you on the best solution. If you decide to replace old machinery with more efficient and more reliable new trucks you may even be able to get the same amount of work done with fewer trucks and at lower cost.

But as we can see from the ‘relocate’ option above, a used forklift with many hours of use isn’t necessarily useless — it may still be able to perform other tasks well, possibly in less intensive or less frequent operations. If you’re thinking about acquiring trucks to fulfil these kinds of tasks, the initial costs will be much lower if you choose used equipment.

If you’re planning on replacing some trucks, and you’re on the lookout for more affordable equipment, get in touch with us about bringing on used equipment — there will be something in our fleet of pre-owned trucks which can still meet your needs. You might just find the truck you’re looking for.